Application

EDM sinker machine is used for cavity forming. It utilizes conductive material (copper, graphite, steel) as electrode to process workpiece (conductive material) by spark erosion. Main use: processing precious die, cavity mold and so on. It is widely used in metal processing and mold making workshop.

EDM sinker machine is used for cavity forming. It utilizes conductive material (copper, graphite, steel) as electrode to process workpiece (conductive material) by spark erosion. It is widely used in mold making workshop. Main use: The precision machining of complex mold cavities, especially complex curved surfaces which are inconvenient for polishing, which can save the manual polishing process, improve the service performance of parts, and has very important practical significance for shortening the mold manufacturing cycle.

Our company's Mirror Die CNC EDM series machines are featured in strong functions, convenient and reliable operation, of fairly good rigidity, running placidly, of good controllability, suitable to process conductive metal moulds, complicated metal parts and templates with high precision, high toughness and difficult processing. EDM process has become the important part in the field of mechanical manufacture.They are widely used in the fields of moulds, electronic instruments, precision mechanical process, automobile parts, military, etc..

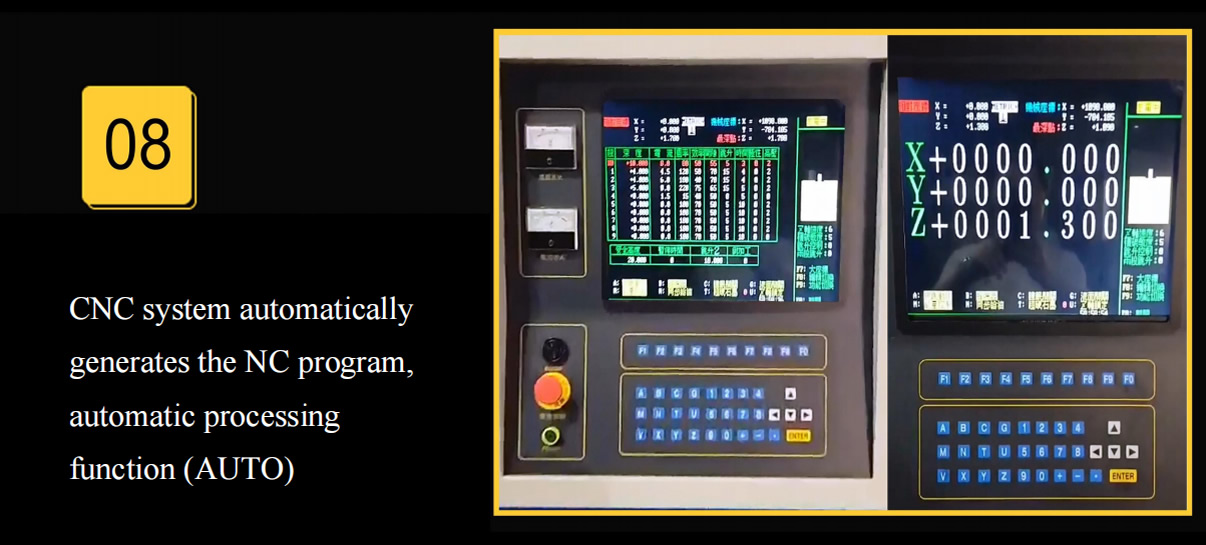

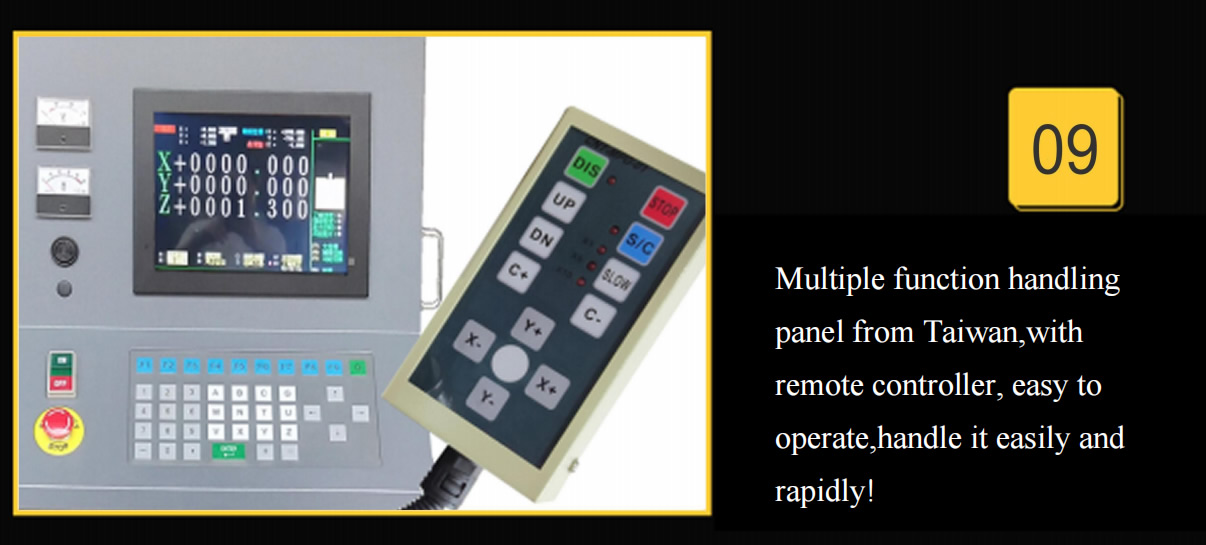

ZNC System Function

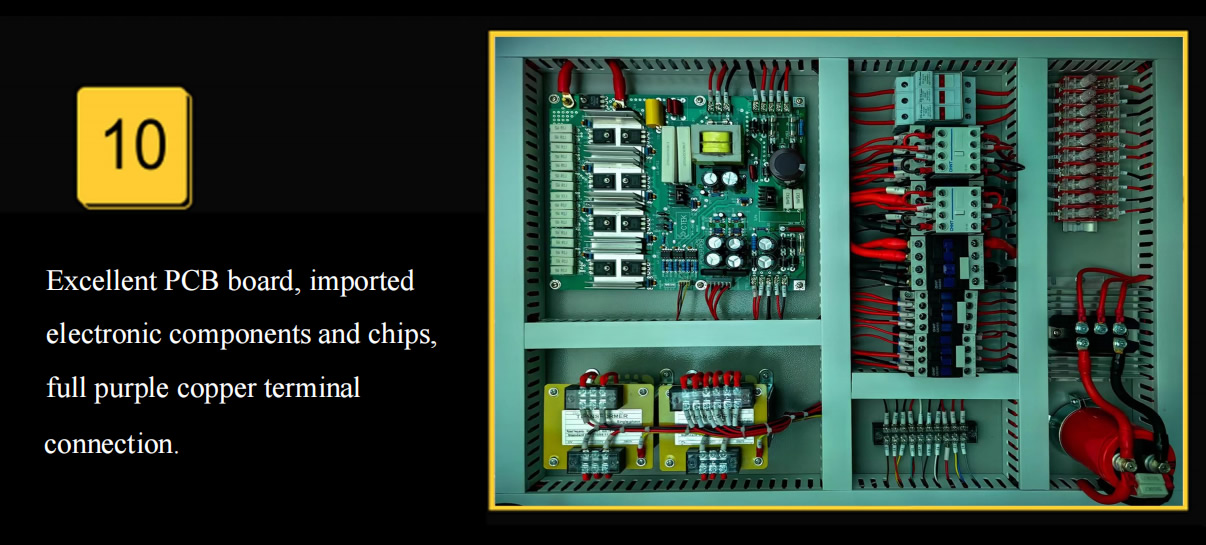

① Main part of the electrical components are purchased from Schneider electric (German company) and Omron company. Adopt three-axis optical digital display. And direction of the optical ruler can arbitrarily change by some code set, Resolution is optional 5 microns or 1 microns.

② Adopt Industrial computer, operation is more easier. Only need to put in the machining depth, the computer will get the parameter from the database from the system.

③ Provide 60 sets of files for storages.

④ There are 10 functions to mended the processed metal automatically:

(1) Program by oneself: You can program the processing conditions depends on your experience;

(2) AUTOZ programs automatically: Giving the biggest depth at the first of electric current and finished choosing thickness or thinness, AUTOZ would program the processing conditions;

(3) Intelligent programmed the conditions: only if choose the shape of electrode, the materials of both of electrode and work piece, the square of the electrode and choice size (thickness / thinness) of processed work piece when finished, the setting of depth, machine can program the processing conditions automatically.

All above three methods of program can submit the way thick-medium- thin and finish the process.

⑤ Adjust release electricity conditions automatically, when releasing electricity unsteadily, the computer would modify electricity efficiency and work time; releasing electricity will recover automatically when stead able. Revise the parameter during the working will not effect the machining.

⑥ Adopt special MOSFET discharge circuit design, machining faster, consuming less and getting more smooth finishing. Be suitable for making deep hole, blind hole, Lateral and any section large area processing for machining,self-discharging carbon alarm and other functions.

⑦ Slowly jump type rate of speed 2 jump about(I am high to jump), it process a stability the big area, the spark line is even, promoting big area electrode to process effectively of speed

⑧ Can the procedure is two high and low flutters, it process deep bore or thin slice of the carbon residue ejects smoothly, prevent froming accumulating carbon, raising deep bore and thin slice to process effectively of efficiency.

⑨ Have to heading up to turn on electricity to process function, make the special work piece process more easily.

⑩ There’s more than 10 kinds color on the screen, the operator can change its color as they like, this give a freshness for their feeling.

? Chinese language and English, the imperial and metric can be changed on the screen as you like, which makes the worker to operate the machine easier than other machines.

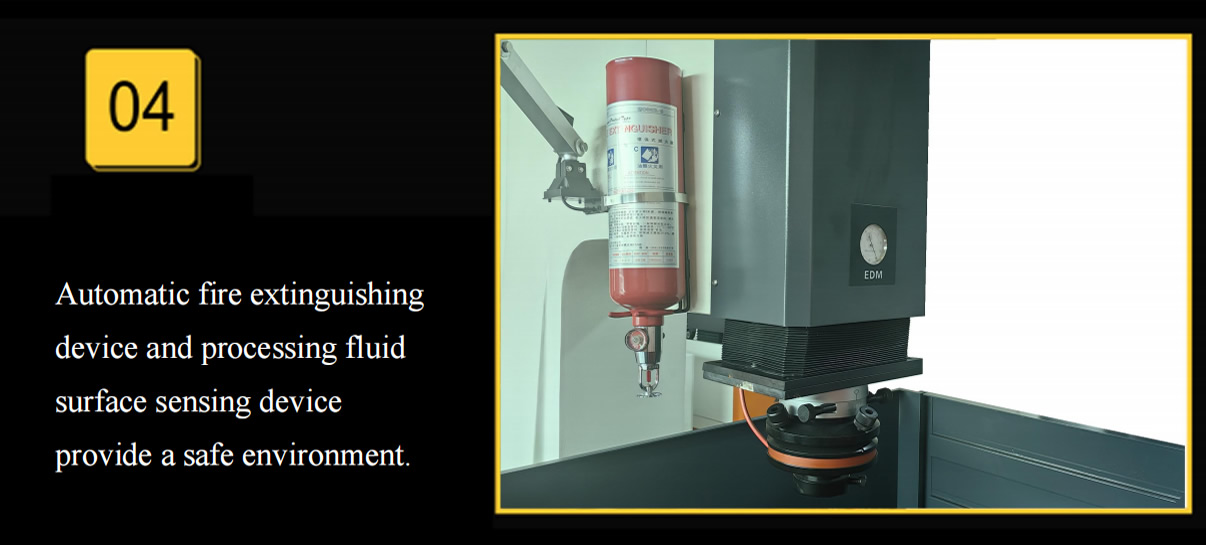

? The machine has the function for ALLM, Infrared flame detection, alarm for finishing the depth and close the power, finding center by itself.

? The controller has the function for changing the Plus-n-Minus, what’s it also has the function of reverse processing.

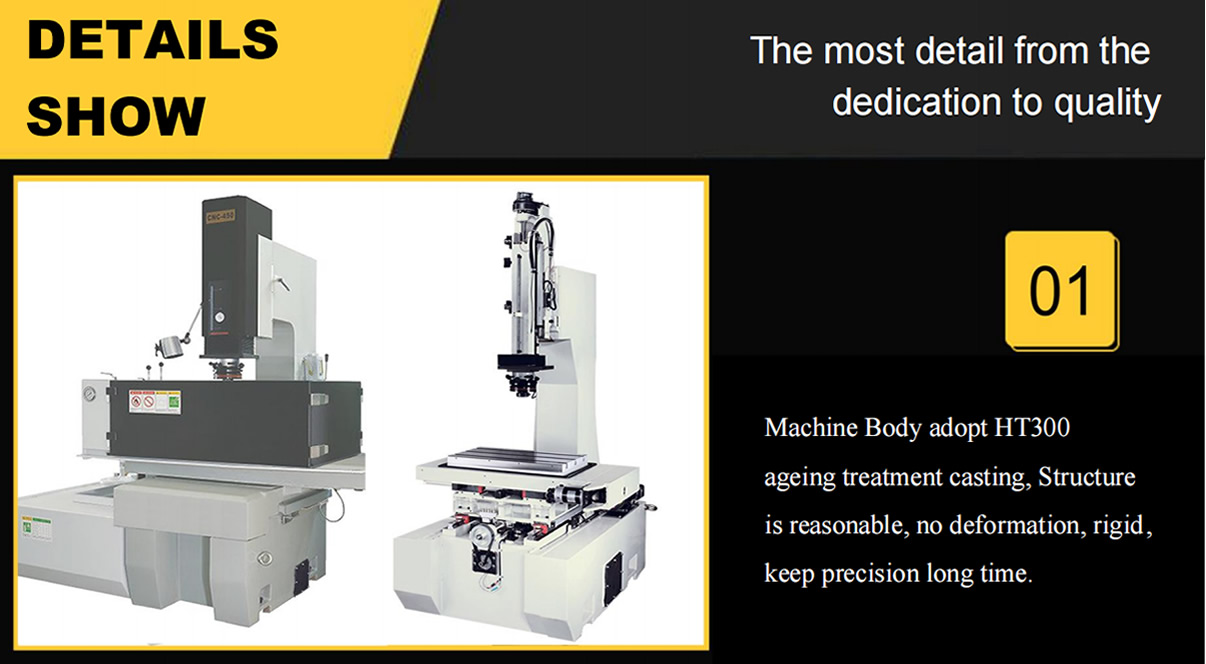

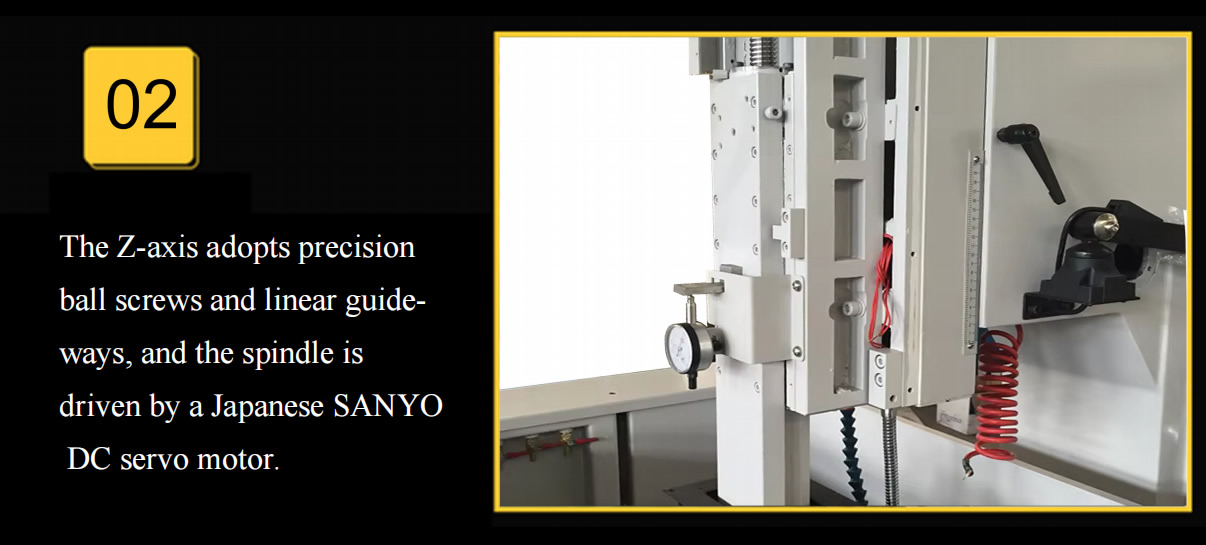

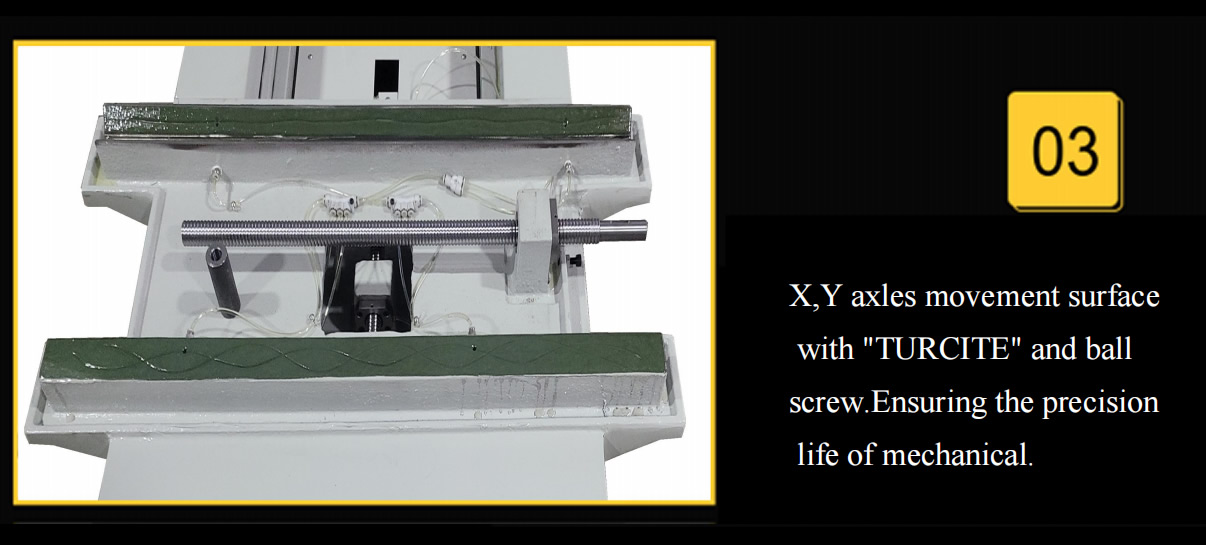

Mechanical Features

Product parameters

Machine body | ZNC430 | ZNC450 | ZNC540 |

The oil tank size (W*D*H) | 1200*680*420mm | 1240*720*420mm | 1380*760*520mm |

Worktable size (X*Y) | 650*350mm | 700*400mm | 850*450mm |

XY axis travel | 400*300mm | 450*350mm | 500*400mm |

W axis travel | 250mm | 250mm | 250mm |

Z axis travel | 200mm | 200mm | 260mm |

Max. distance from worktable to flat surface of electrode. | 620mm | 690mm | 700mm |

Max. electrode wight | 80kgs | 90kgs | 100kgs |

Max. workpiece size | 1000*600*560mm | 1050*650*560mm | 1150*600*560mm |

Max. workpiece weight | 800kgs | 800kgs | 1000kgs |

Out size | 1450*1150*1980mm | 1470*1250*1980mm | 1640*1460*2140mm |

Packing dlimension (W*D*H) | 1600*1350*2400mm | 1600*1400*2400mm | 2150*1800*2300mm |

Net weight (approx.) | 1350kgs | 1550kgs | 1850kgs |

Gross weight (approx.) | 1500kgs | 1750kgs | 2100kgs |

Pulse Power | |||

CNC Control system | ZNC | ZNC | ZNC |

Standard | 3×380V ±10% ,50/60Hz | 3×380V ±10% ,50/60Hz | 3×380V ±10% ,50/60Hz |

Electrode consume | <0.2% | <0.2% | <0.2% |

Tiptop surface roughness | 0.18μmRa | 0.18μmRa | 0.18μmRa |

Max. working current | 60A | 60A | 60A |

Max. maching speed | 460mm3/min | 460mm3/min | 460mm3/min |

Control box dimension | 820*720*1850mm | 820*720*1850mm | 820*720*1850mm |

Package size (W*D*H) | 900*750*2000mm | 950*850*2100mm | 900*750*2000mm |

Net weight | 250kgs | 180kgs | 250kgs |

Gross weight | 380kgs | 250kgs | 380kgs |

Menu Language | Chinese/English | Chinese/English | Chinese/English |

Dimension | Metric/Inch | Metric/Inch | Metric/Inch |

Power Supply | |||

Standard | 3×380V ±10% ,50/60Hz | 3×380V ±10% ,50/60Hz | 3×380V ±10% ,50/60Hz |

Other supply | 110V~415V | 110V~415V | 110V~415V |

Working temperature | 10-35℃ | 10-35℃ | 10-35℃ |

Input current | 5.5KVA | 5.5KVA | 5.5KVA |

Oil box unit | |||

oil box capacity | 400Liters | 430Liters | 550Liters |

Oil box net weight | 180kgs | 100kgs | 180kgs |

Oil box gross weight | 250kgs | 150kgs | 250kgs |

Package size (W*D*H) | 1150*1000*950 | 1150*1000*950mm | 1250*1100*950 |

管理員

該內(nèi)容暫無(wú)評(píng)論